Low Spatter Arc (LSA)

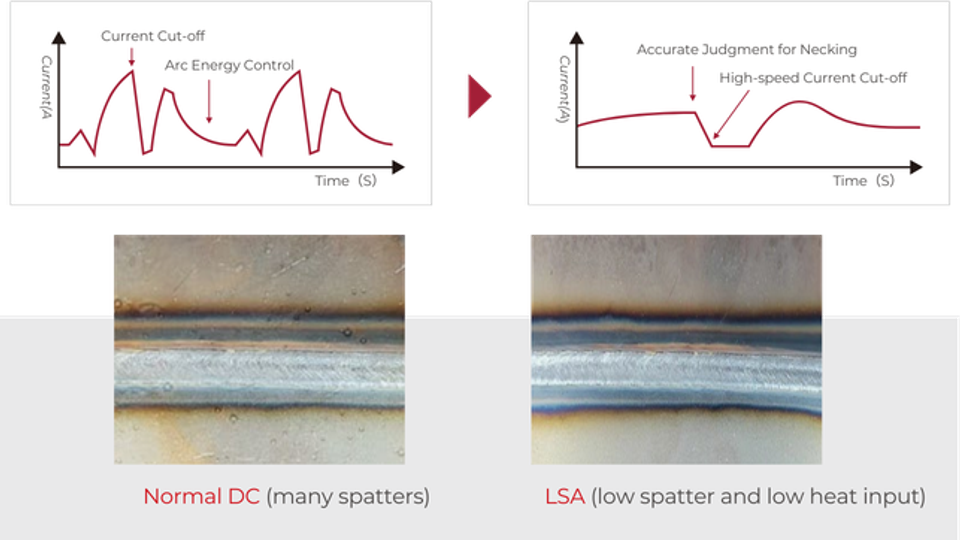

Advanced LSA technology reduces spatter by over 50% compared to conventional MIG welding, delivering cleaner welds and less post-weld cleanup.

Full Digital IGBT Inverter Multi-functional MIG Welding Machine

The Megmeet Dex2 M Series delivers exceptional MIG/MAG welding performance with advanced LSA (Low Spatter Arc) technology that reduces spatter by over 50%. Available in DC, Pulse, and Quick Pulse variants for manual and robotic applications across engineering machinery, steel structures, and automotive manufacturing.

Equipped with 400V high-voltage touch sensing (80–400V range) for accurate workpiece detection and positioning, especially useful in robotic welding applications.

Features U-disk firmware upgrades and SMARC IoT interface for real-time welding data monitoring, welder management, and production reporting through cloud-based smart welding platforms.

Rated at 100% duty cycle at full output current, the Dex2 M Series is built for continuous heavy-duty industrial welding without downtime.

Advanced LSA technology reduces spatter by over 50% compared to conventional MIG welding, delivering cleaner welds and less post-weld cleanup.

QPT increases welding speed by over 20% compared to conventional pulse welding, boosting productivity while maintaining excellent weld quality.

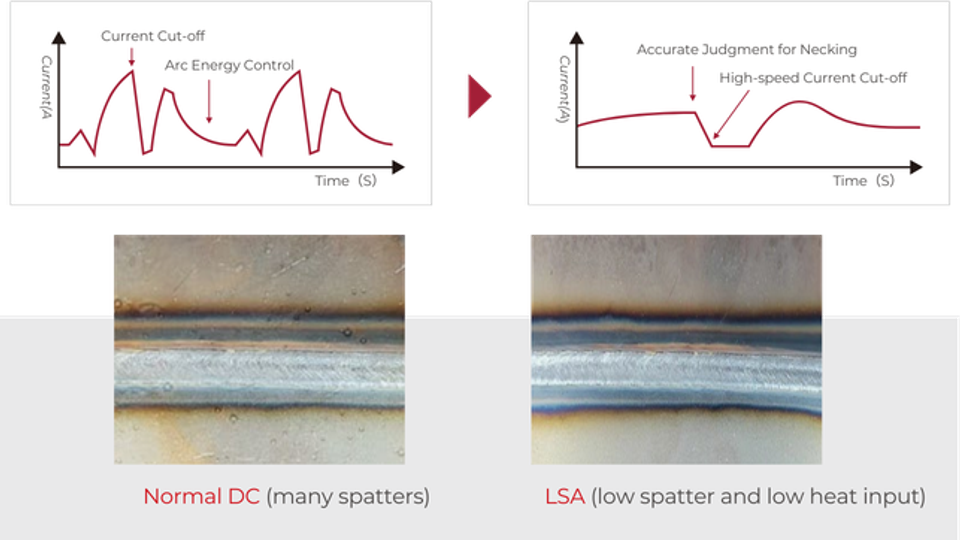

The Dex2 M Series uses chopper control technology for precise droplet control during welding, ensuring consistent and high-quality weld beads across all welding positions and materials.

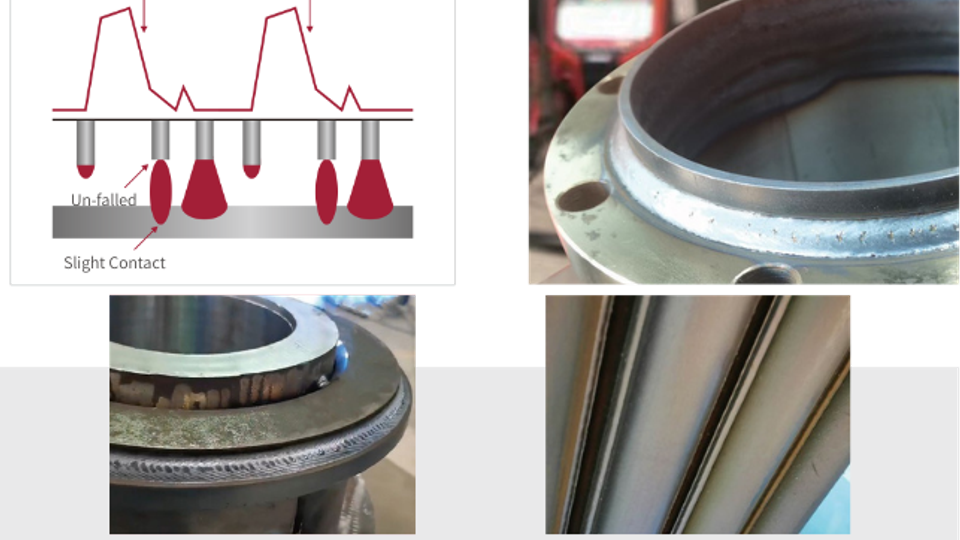

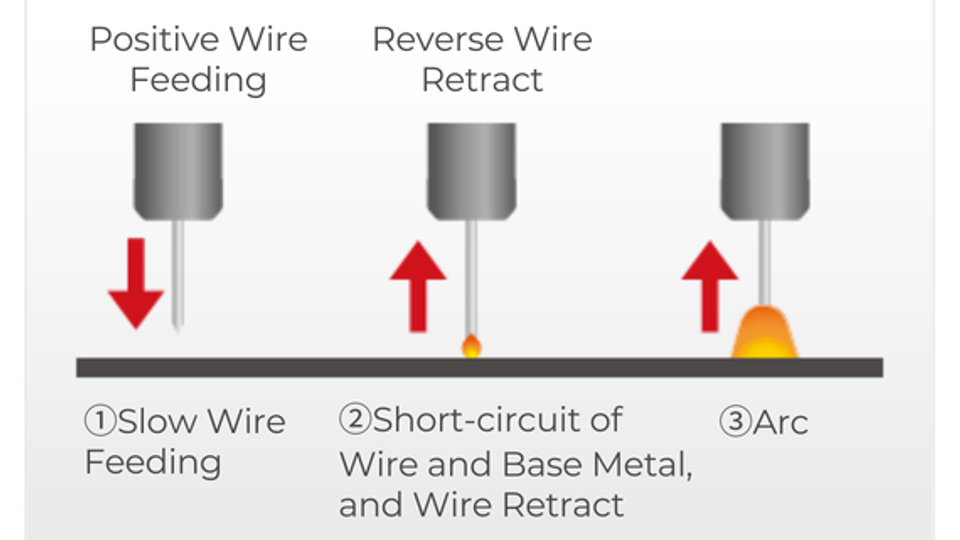

Nearly 100% arc-start success rate thanks to adaptive retraction technology. The system intelligently adjusts arc initiation parameters for reliable starts every time, reducing material waste and rework.

Fill out the form below to get customized laser cutting samples and professional service support from our regional sales managers.