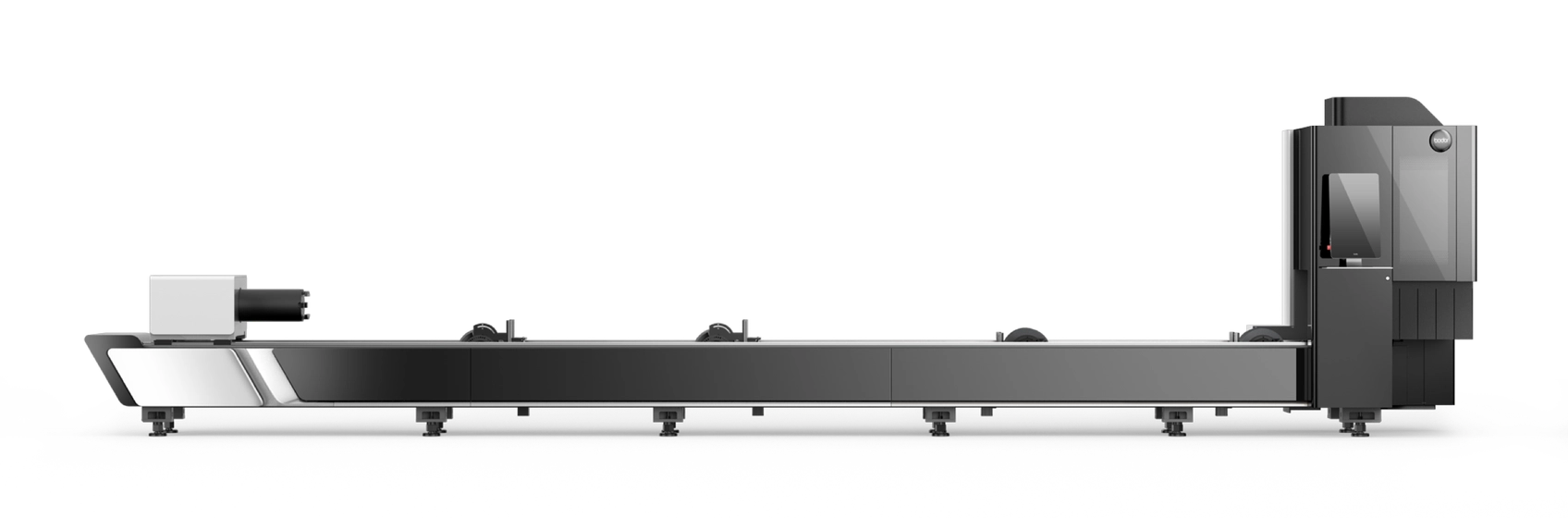

Intelligent chuck

K series’ pneumatic chucks are well-suited for stable performance in dynamic applications. Each of the two chucks is able to complete clamping in just 2 seconds with a strong chucking force. It also reduces scrap to only 45 mm, limiting waste and facilitating regular on-site maintenance.