Thought Leadership

Understanding the Technical Specifications of Fiber Laser Cutting Machines: Key Specs and What They Mean

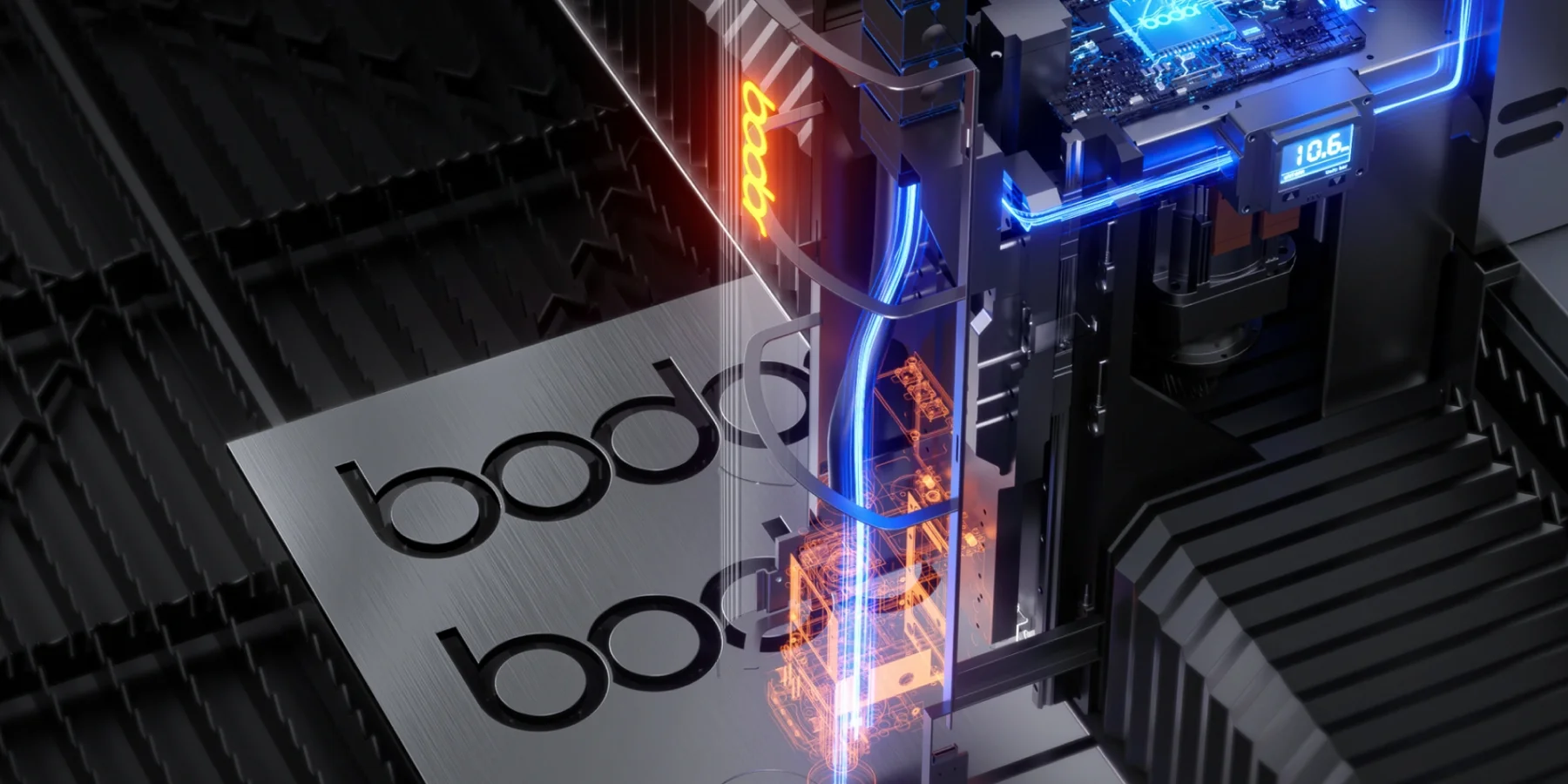

Fiber laser cutting machines are revolutionizing the manufacturing industry, providing precision and efficiency that traditional cutting methods can't match. However, understanding the technical specifications of these machines can be daunting. This guide will break down the key specs and what they mean, making it easier for you to choose the right machine for your needs.

Laser Power (Watts)

The laser power, measured in watts (W), determines the cutting ability of the machine. Higher wattage allows for cutting thicker and tougher materials. Common laser powers range from 3000W to 12kW. For example, a 3kW laser can cut through 12mm thick mild steel, while a 6kW laser can handle up to 25mm.

Cutting Speed

Cutting speed refers to how quickly the machine can cut through material, typically measured in meters per minute (m/min). This speed varies based on the material type and thickness. Higher cutting speeds improve productivity but require careful balancing with precision.

Cutting Area

The cutting area defines the maximum dimensions of material the machine can handle, usually specified in millimeters (mm) or meters (m). For instance, a cutting area of 3000mm x 1500mm means the machine can cut materials up to 3 meters long and 1.5 meters wide. Ensure the cutting area matches your typical material sizes.

Positioning Accuracy and Repeatability

Positioning accuracy measures how precisely the machine can follow the intended cutting path, often denoted in microns (um). Repeatability indicates the machine's ability to return to the same position during repeated operations. High accuracy and repeatability are crucial for detailed and consistent cuts.

Cooling System

Fiber laser cutting machines generate significant heat, requiring efficient cooling systems. Water-cooled systems are common, ensuring the laser and components maintain optimal operating temperatures to prevent overheating and ensure longevity.

Assist Gas

Assist gas, such as oxygen, nitrogen, or compressed air, is used to blow away molten material and improve cutting quality. Different gases are chosen based on the material being cut. For example, nitrogen is often used for stainless steel to prevent oxidation and achieve cleaner cuts.

Control System and Software

The control system and software interface with the machine, allowing operators to design and execute cutting tasks. User-friendly software with advanced features like nesting (optimizing material usage) and remote monitoring can significantly enhance productivity and ease of use.

Table Type

The table type can be fixed or exchangeable. Exchangeable tables allow for continuous operation by loading and unloading materials on one table while cutting on another, thereby reducing downtime and increasing efficiency.

Conclusion

Understanding these key technical specifications will help you make an informed decision when selecting a fiber laser cutting machine. By considering factors such as laser power, cutting speed, and control systems, you can choose a machine that best meets your needs and maximizes your production capabilities.